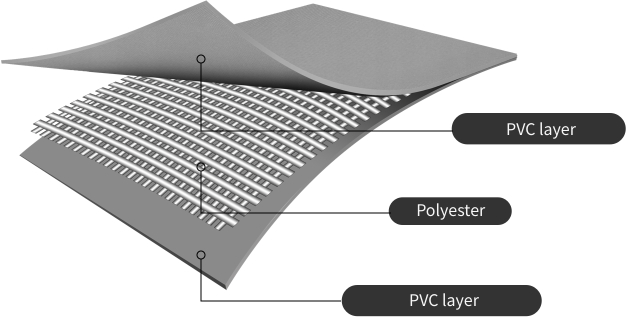

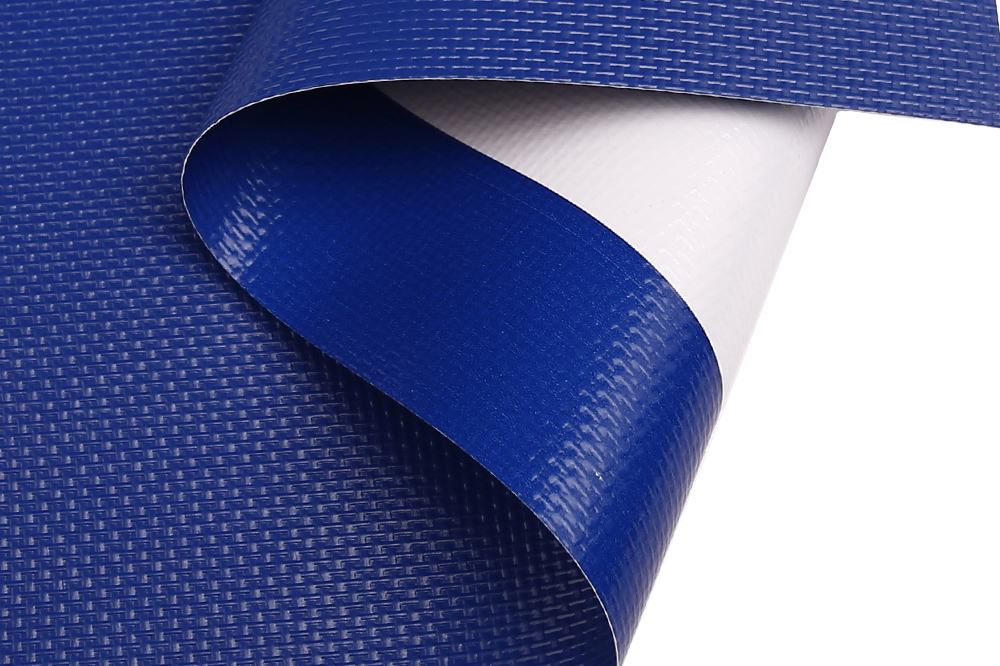

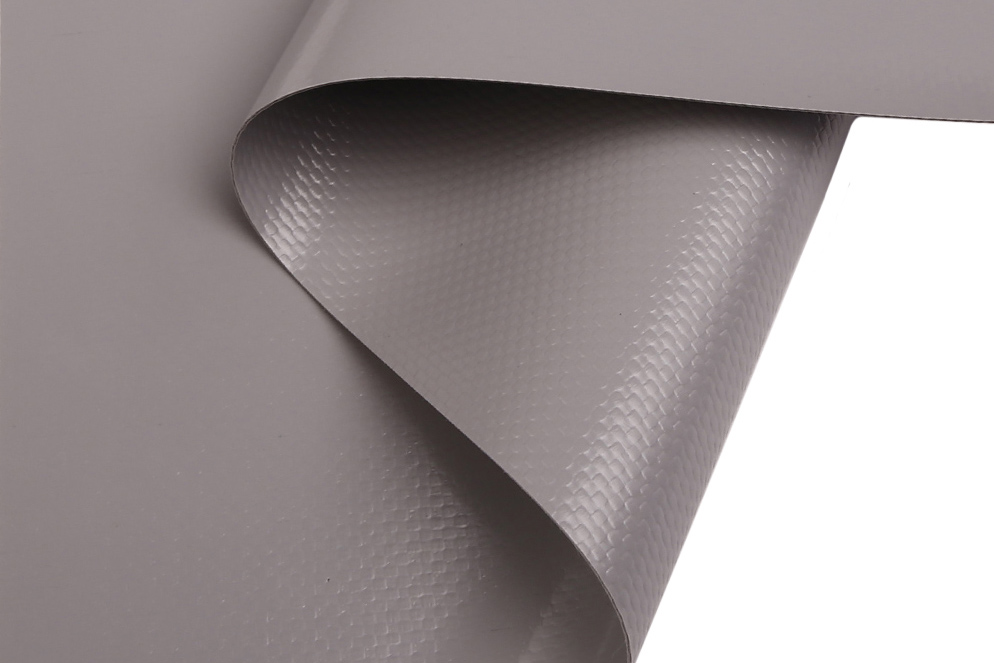

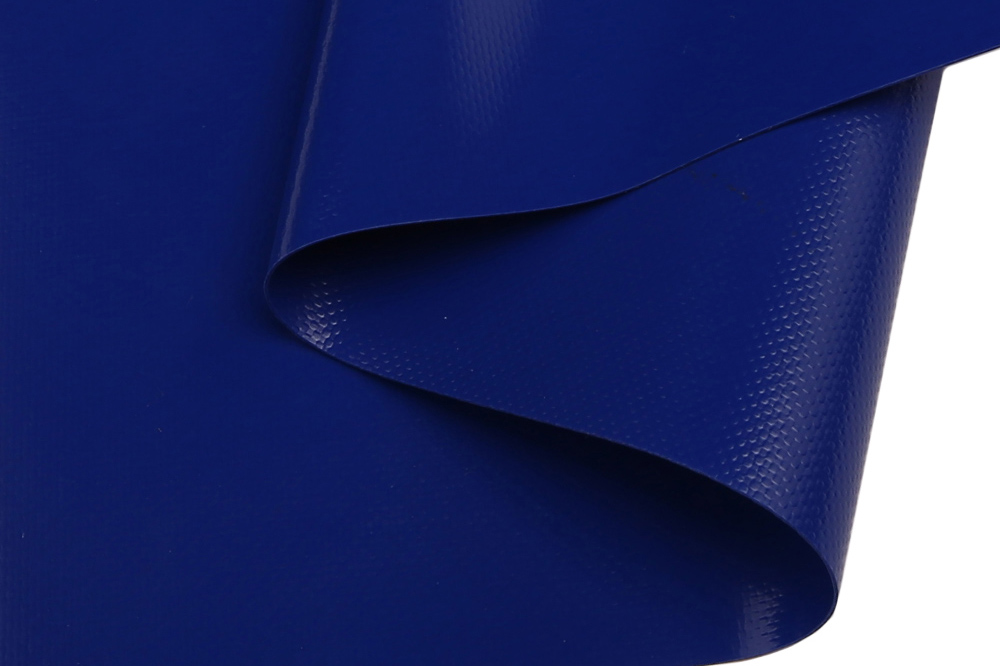

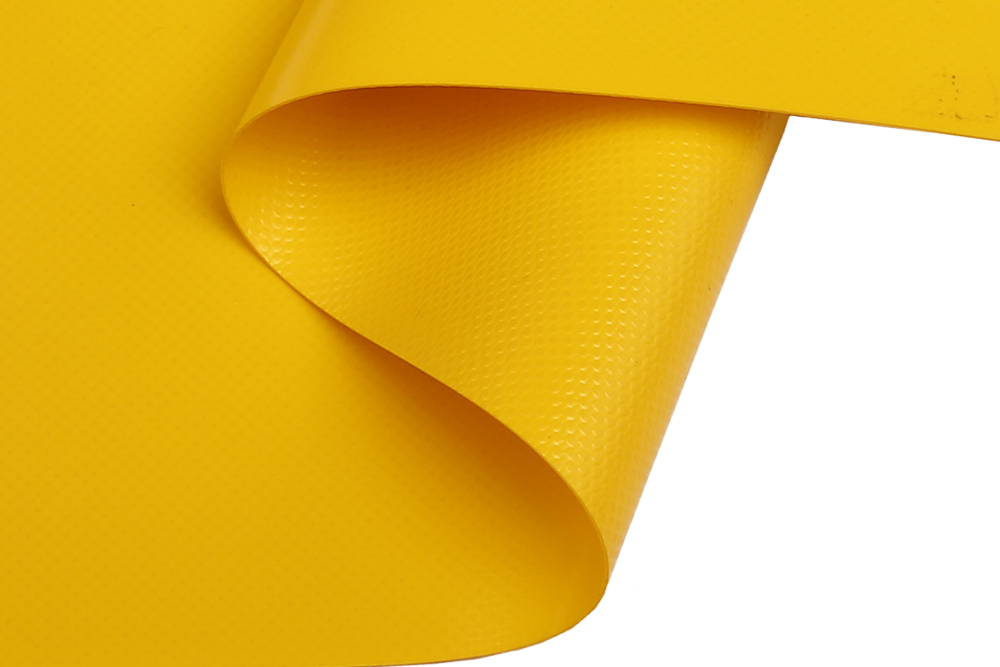

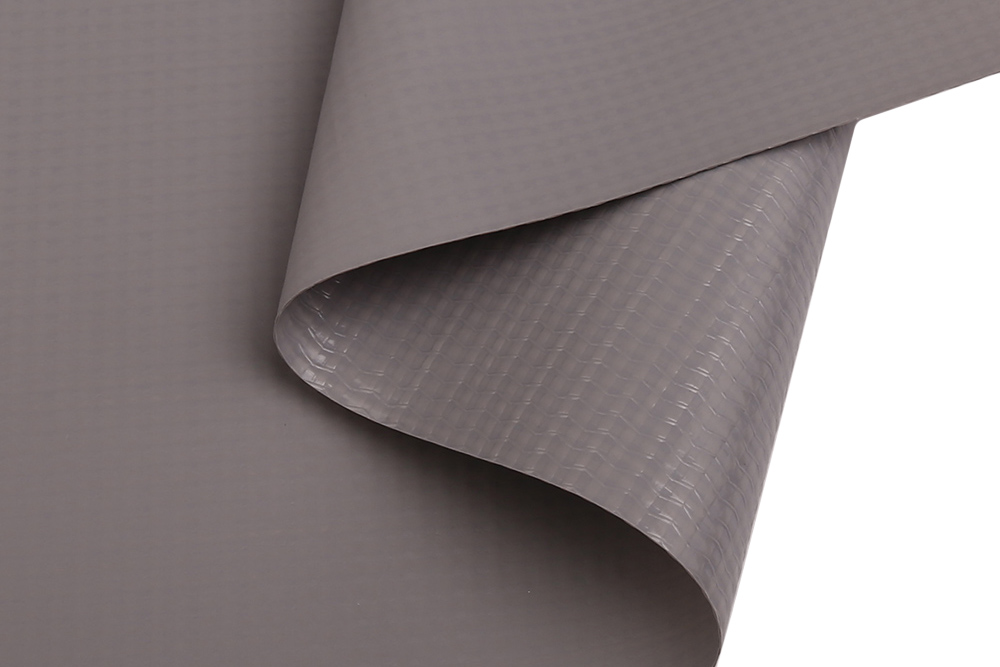

PVC tarpaulin is a three-ply waterproof fabric, which is based on high-strength polyester, coated with polyvinyl chloride (PVC) paste resin added with various chemical additives such as anti-fungal additive, anti-aging additive and anti-static additive, and then plasticized at high temperature. It has the properties of waterproof, antibacterial, cold resistance, aging resistance, anti-static, etc. The anti-aging effect of PVC tarpaulin is far better than that of PP and PE tarpaulin.

Details of PVC Tarpaulin:

| Product Name: | PVC Tarpaulin |

| Material: | PVC+Polyester |

| Polyester Denier: | 200D/500D/840D/1000D/1500D,etc |

| Gram Weight: | 200gsm-2000gsm |

| Color: | White, Black, Grey, Green, Blue, Yellow, Red, etc |

| Working Life: | More than 5 years |

| Features: | Waterproof, High Tensile Strength, Fire Retardant, Anti UV, Heavy Metal Free, Anti Mildew, Flexible, Heavy Duty, Self Clean, etc are available |

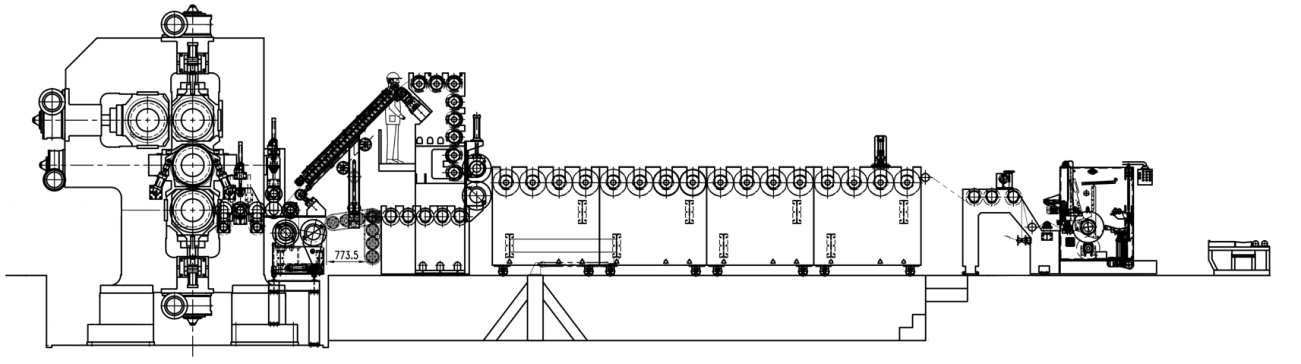

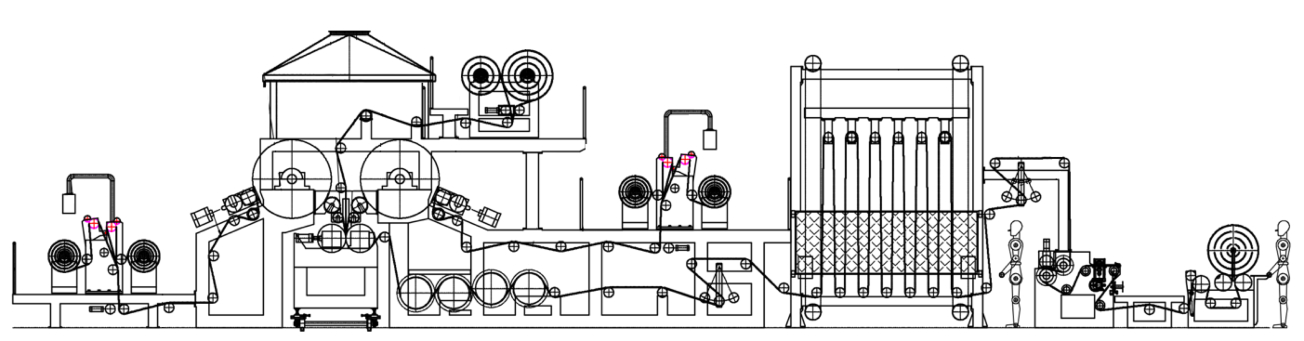

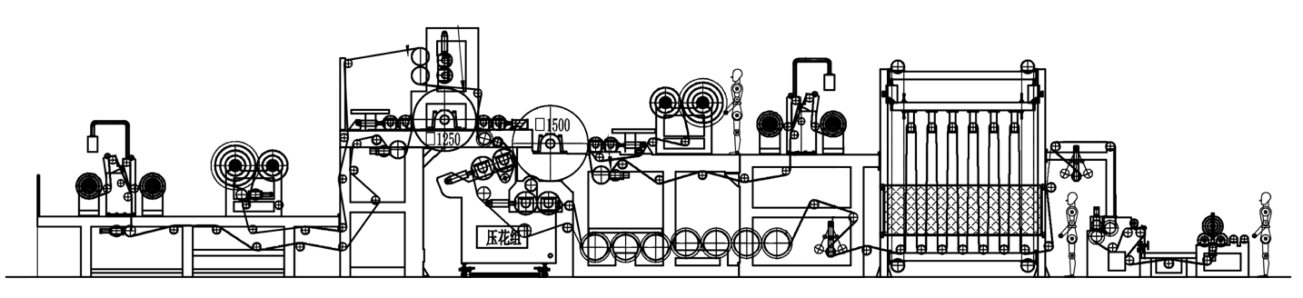

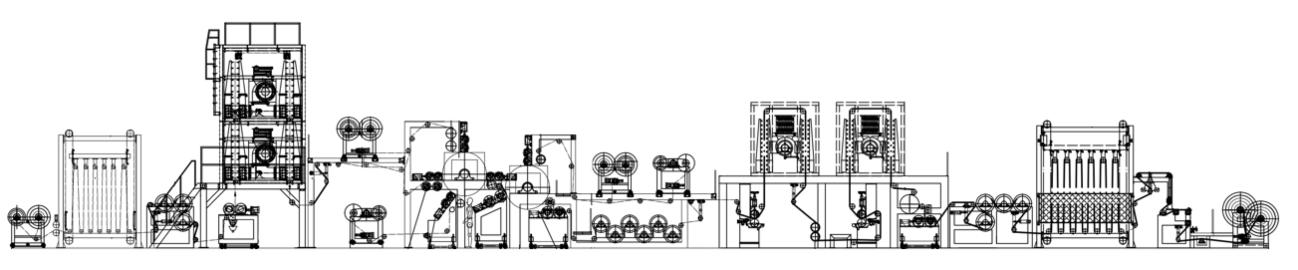

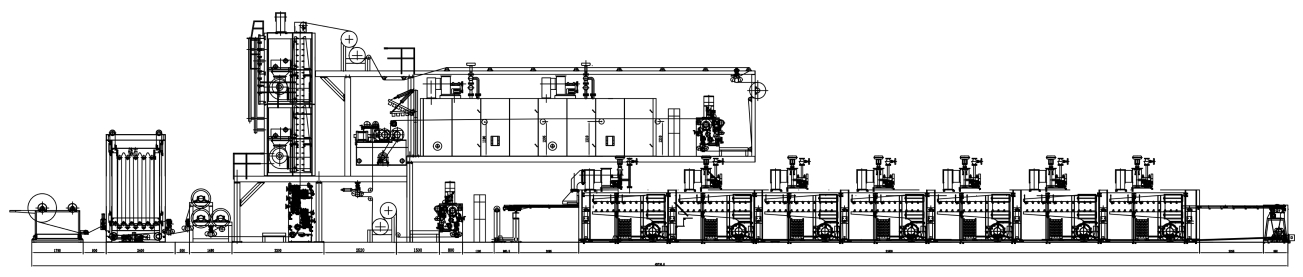

In the manufacturing process of PVC tarpaulin fabrics , various machines are employed for different fabric specifications:

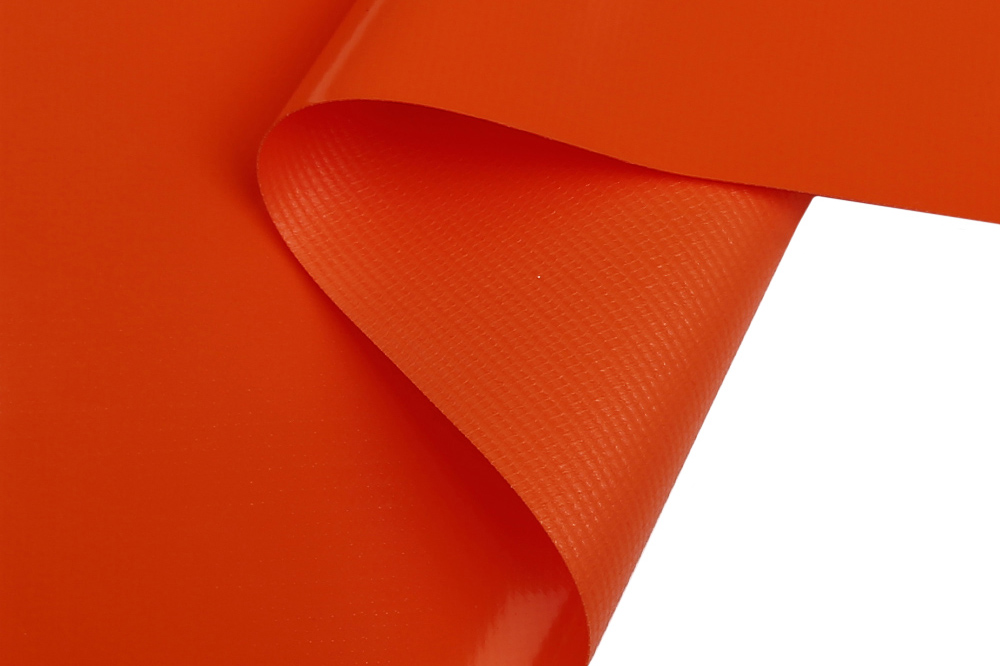

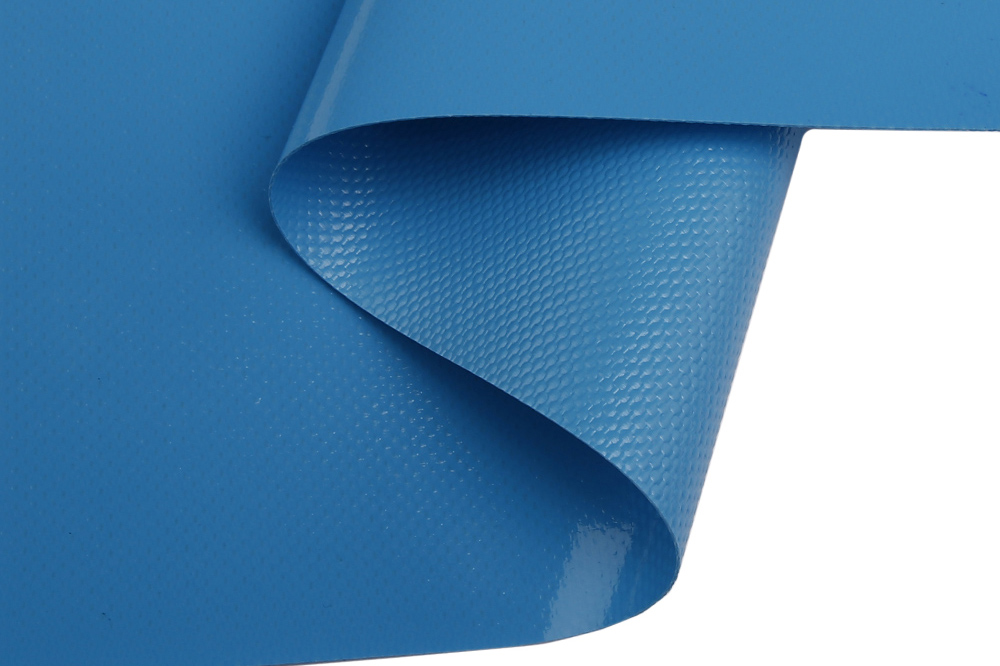

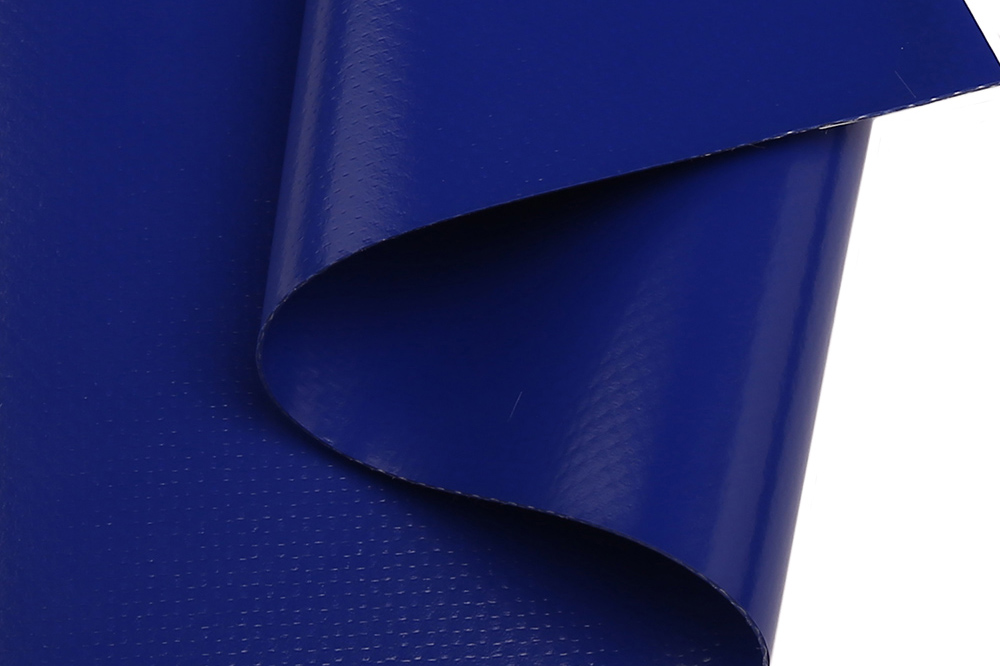

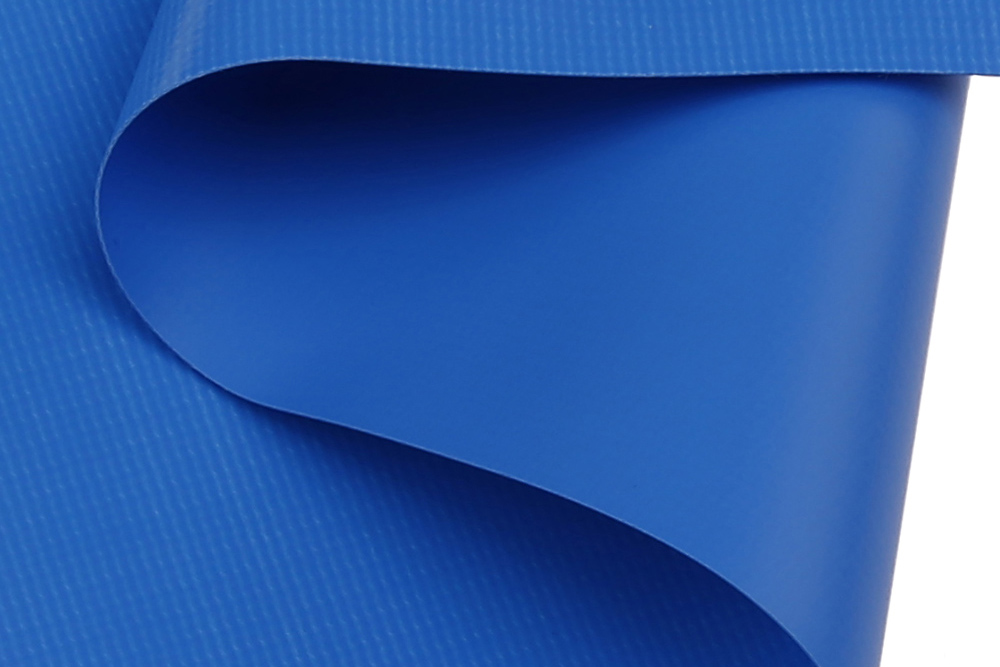

- Calendering Machine: Transforms PVC raw material into paste and calenders it into different thicknesses of PVC film using a roller system. The film is bonded to polyester backing and finished with gloss, matte, or embossed textures.

- Cold Lamination Machine: Used for laminating PVC films onto polyester fabric quickly and cost-effectively, often for lower-priced products.

- Hot Lamination Machine: Advanced version of cold lamination, offering higher quality and durability. It can apply acrylic coatings for self-cleaning and enhance adhesion for semi-coated PVC tarpaulin.

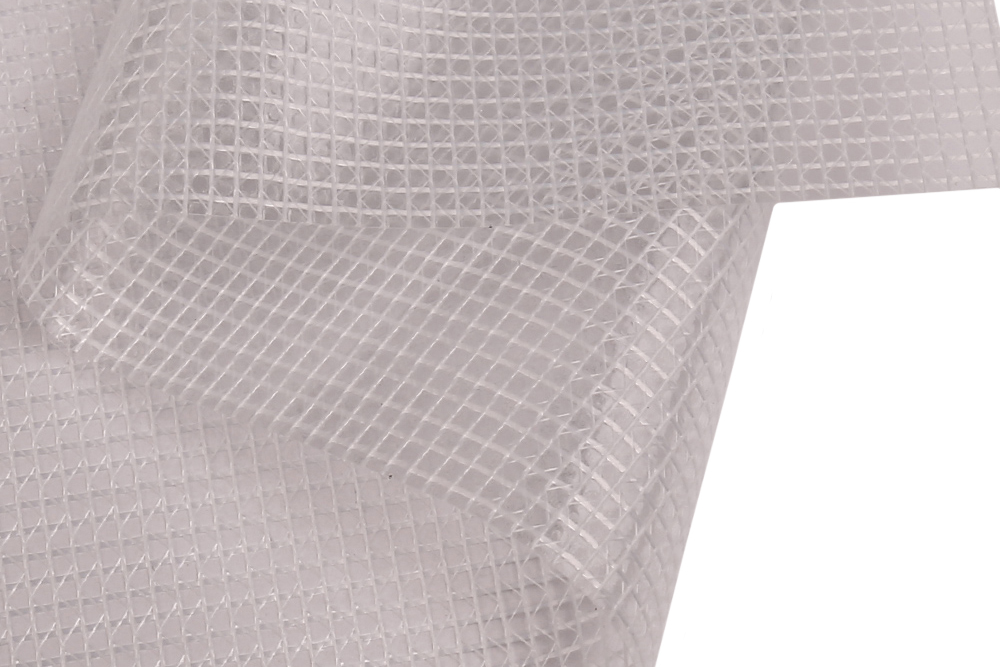

- Semi-Coated Machine: Its primary task is to bond two or more different materials together through coating or adhesive, creating a composite material. This can provide enhanced strength, waterproofing, and other performance characteristics.

- Coating Machine: Primary function is to evenly apply liquid or powder materials onto the surface of a substrate to create a uniform coating, thereby enhancing the material's performance and appearance.

Product Features:

• Excellent Strength: The fiber reinforcement layer provides PVC tarpaulin with remarkable tensile strength and tear resistance, making it highly durable and suitable for a variety of applications.

• Good Flexibility: The combination of PVC film and fiber reinforcement imparts flexibility to the tarpaulin, enabling it to conform to different shapes and curves.

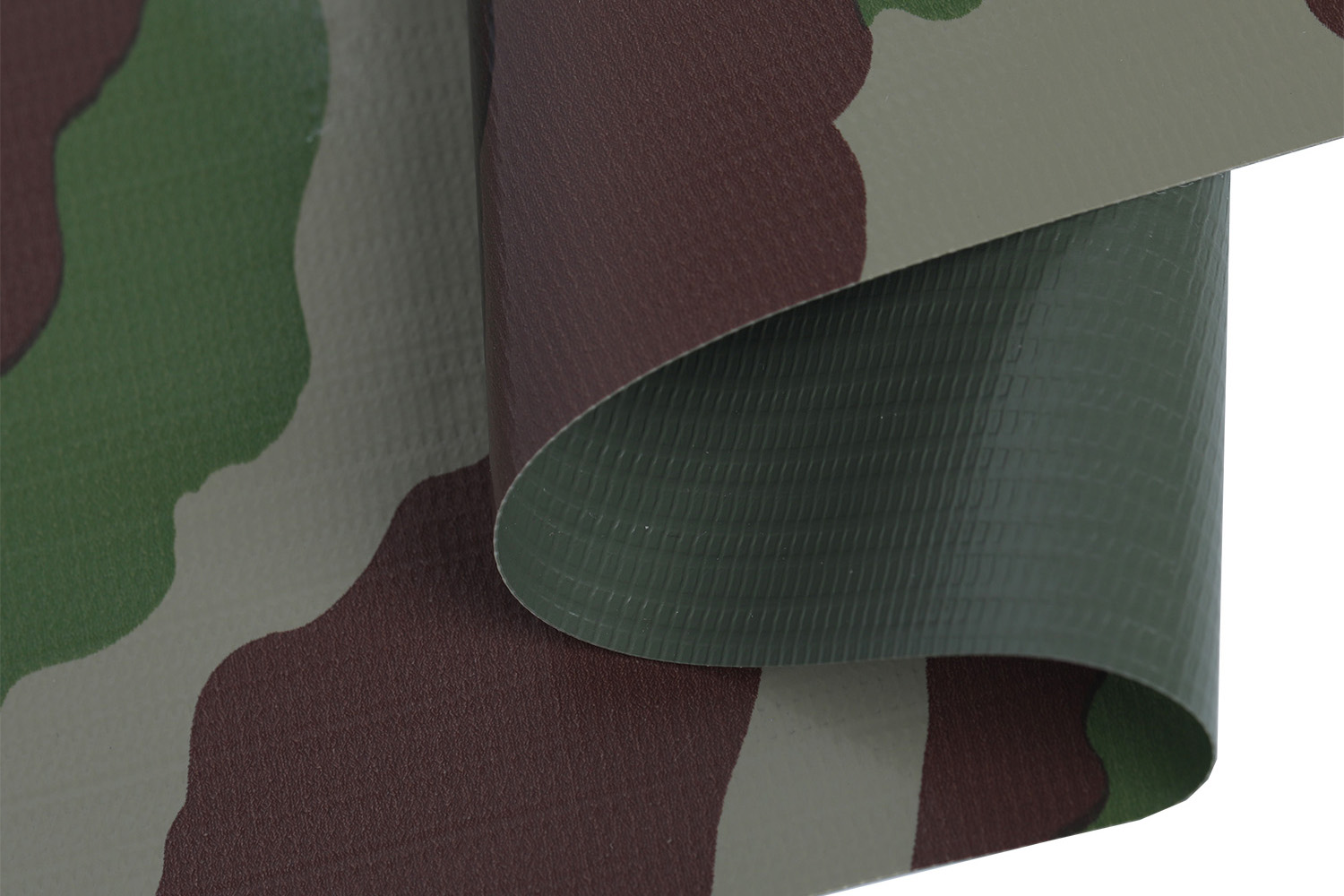

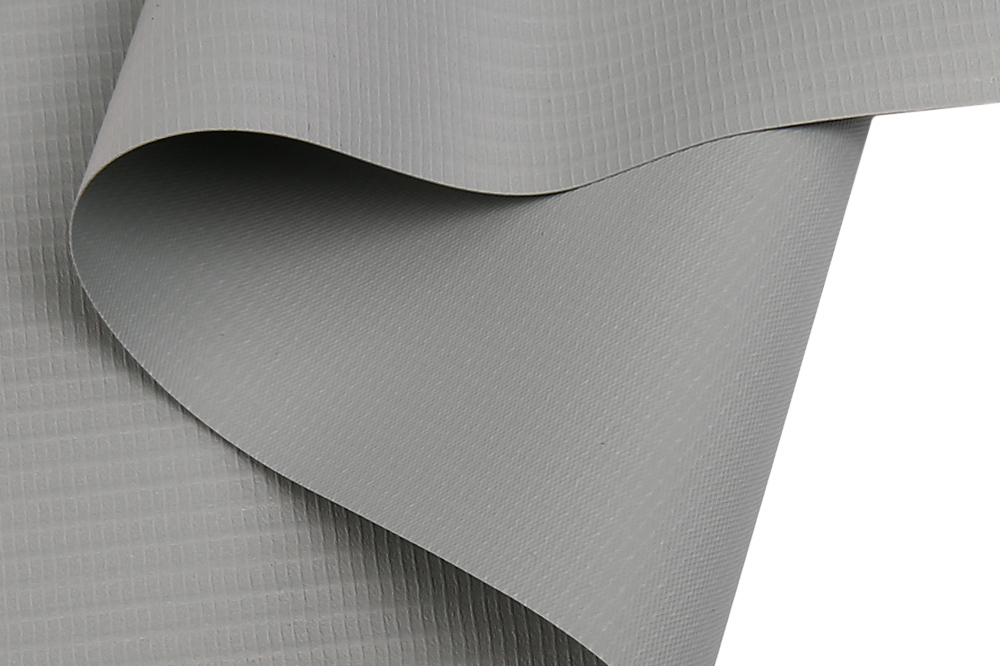

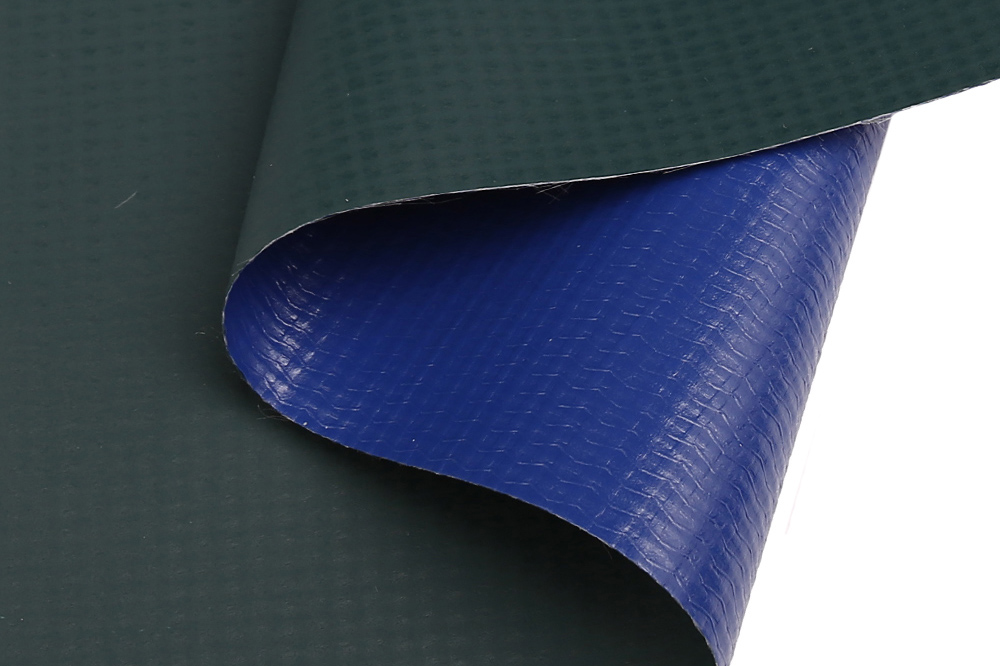

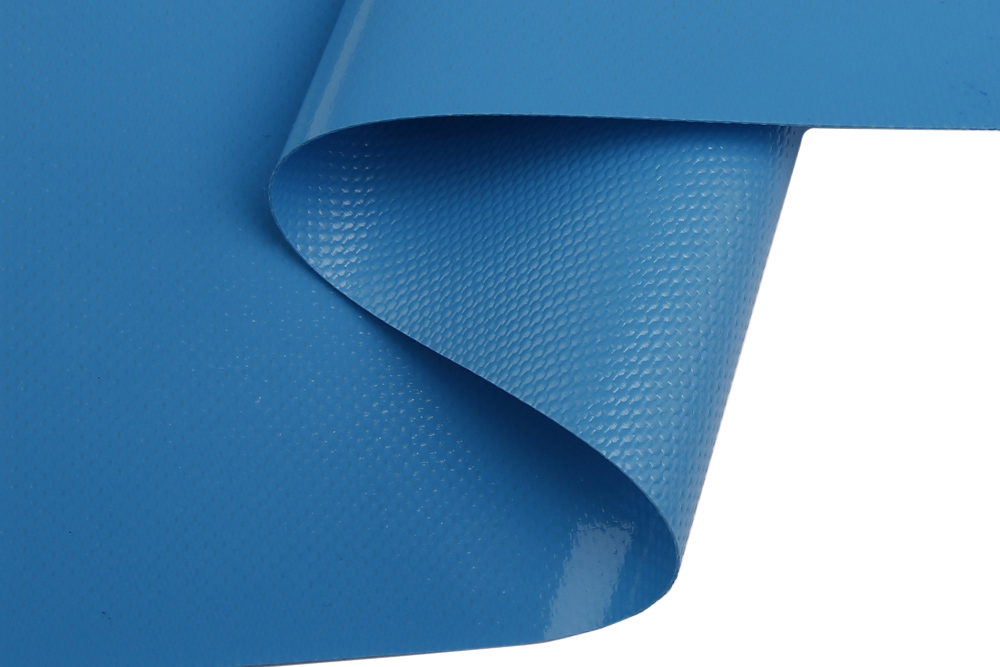

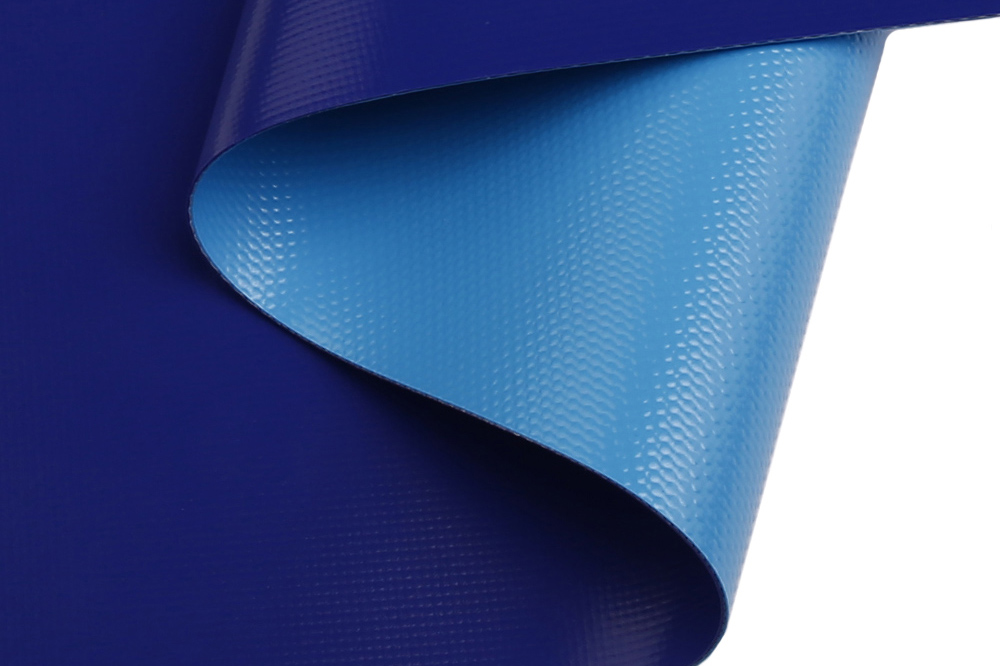

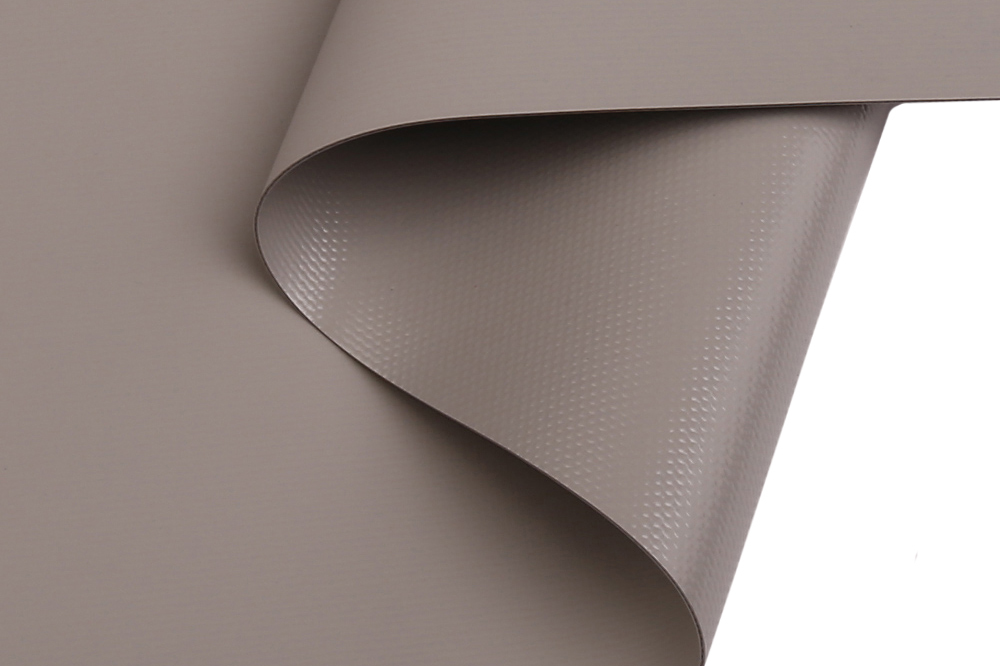

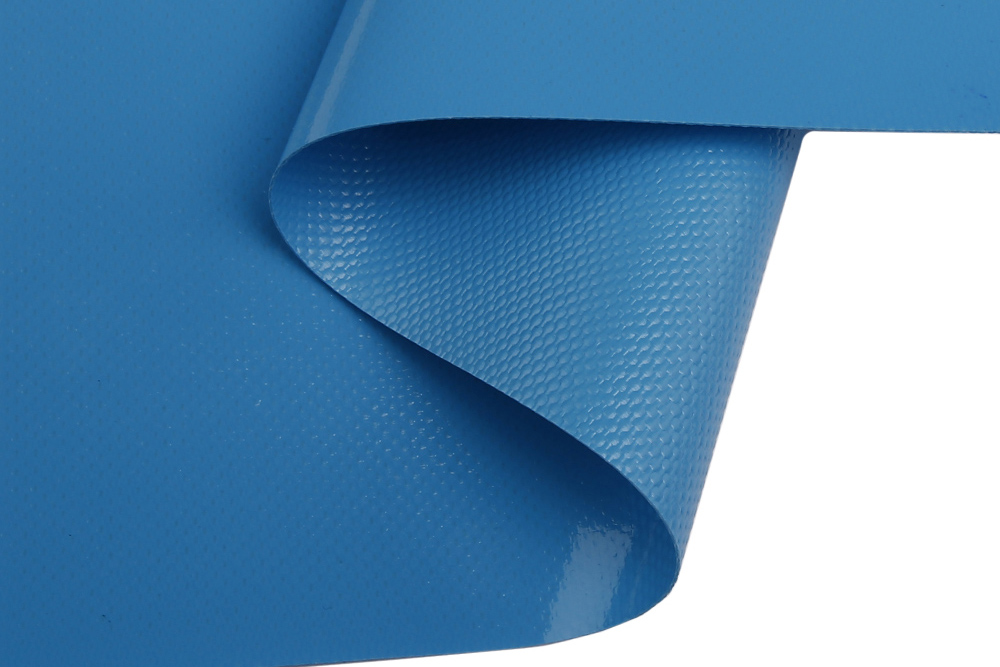

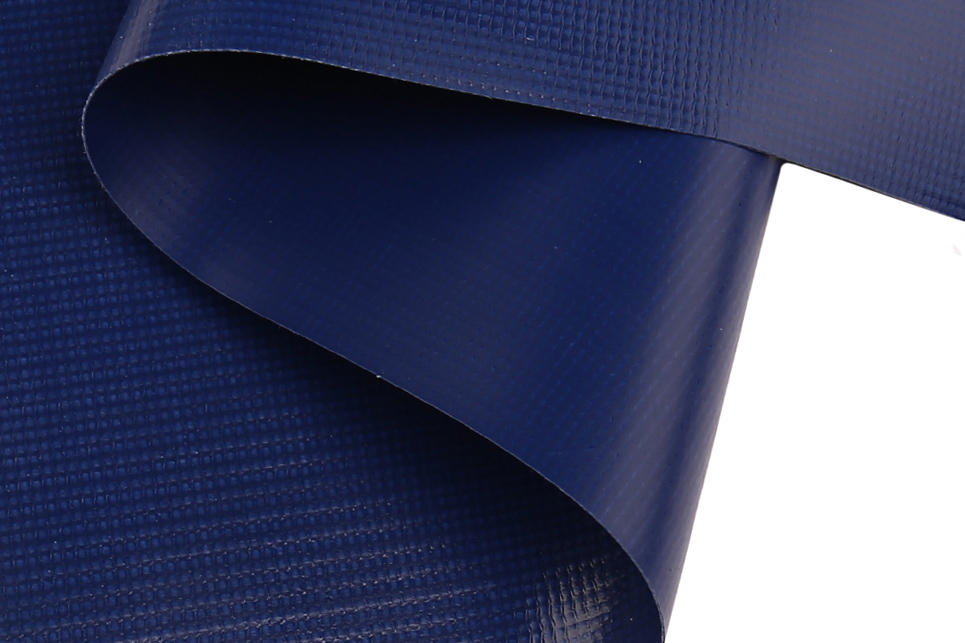

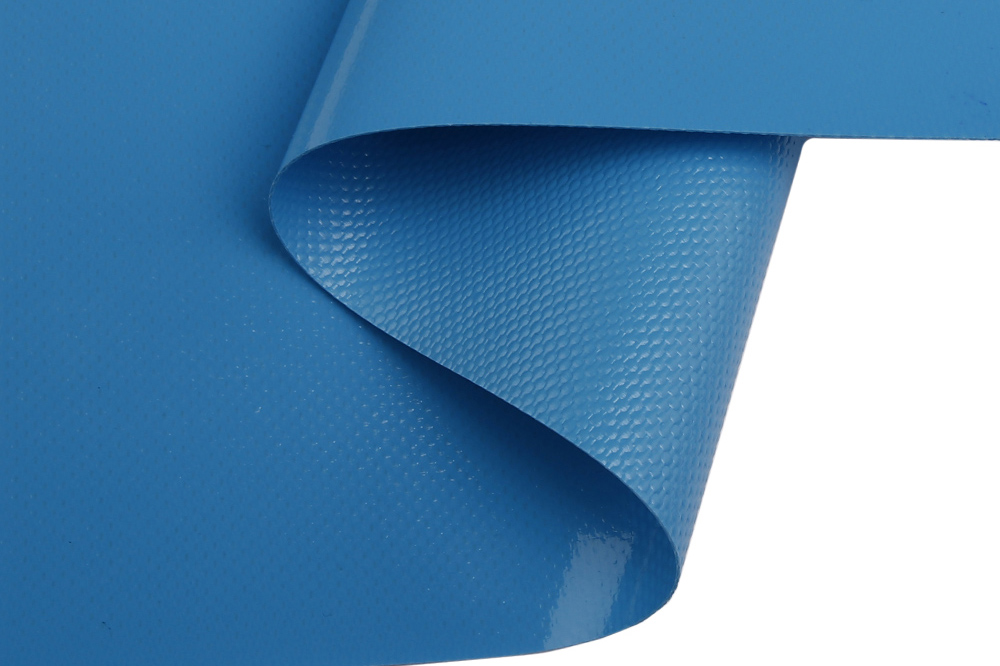

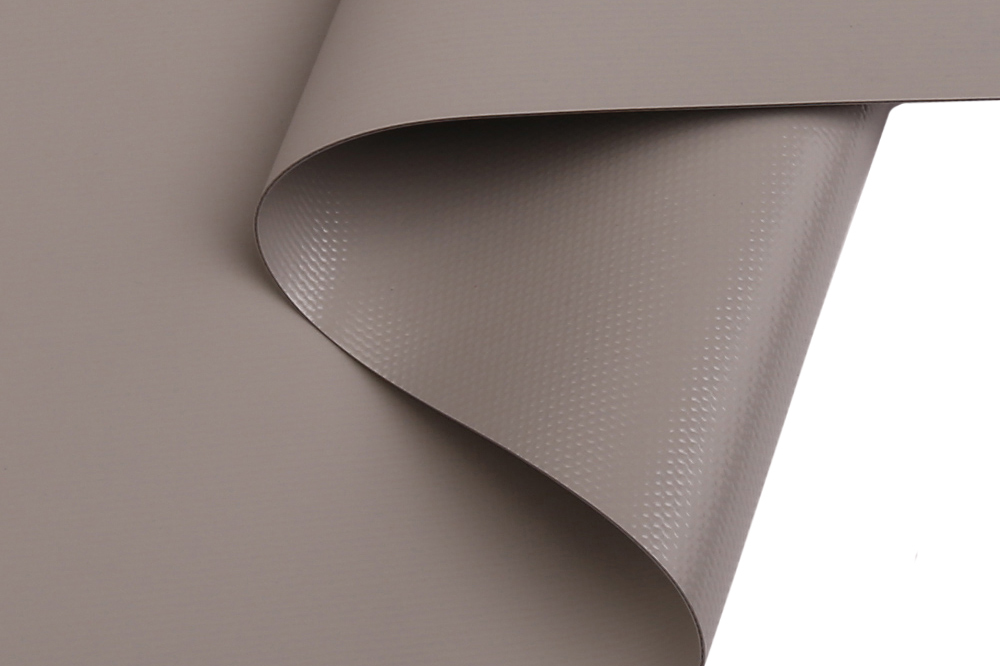

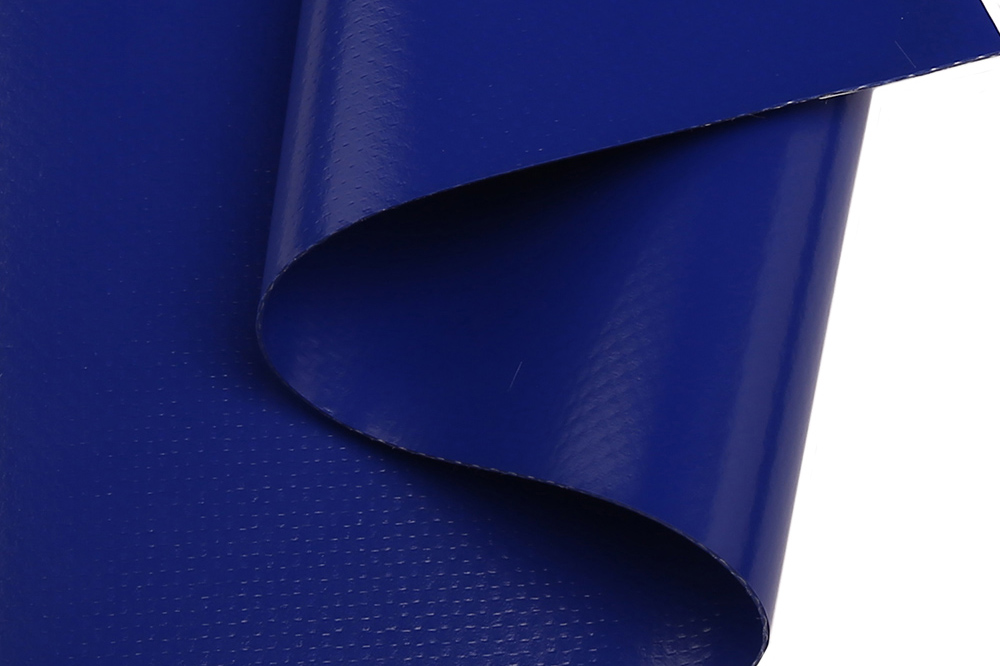

• Diverse Surface Textures: During the manufacturing process, tarpaulin undergoes embossing, resulting in various surface textures such as matte, taffeta, and polished finishes. These textures not only influence visual appearance but also affect light reflection and smoothness.

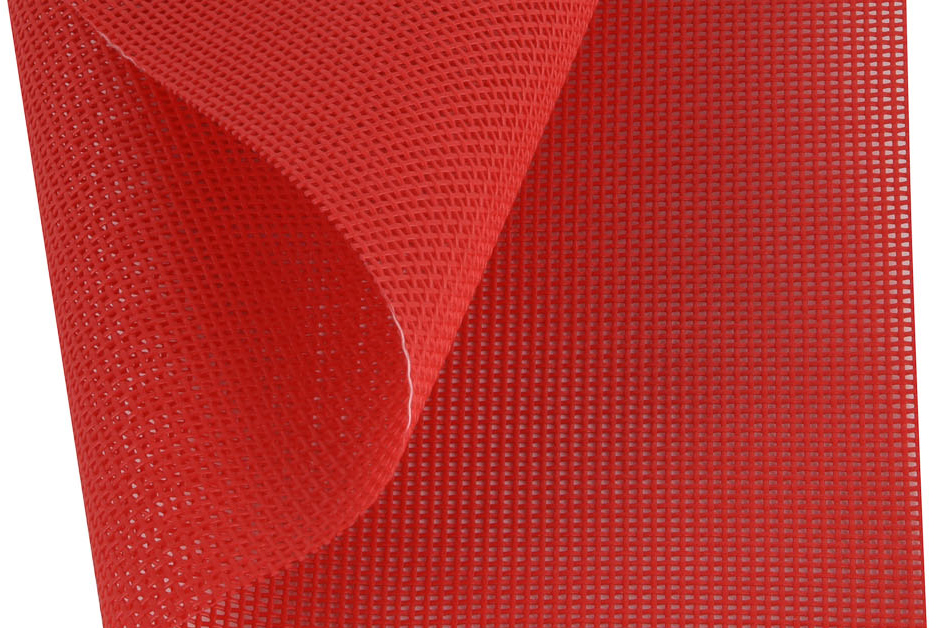

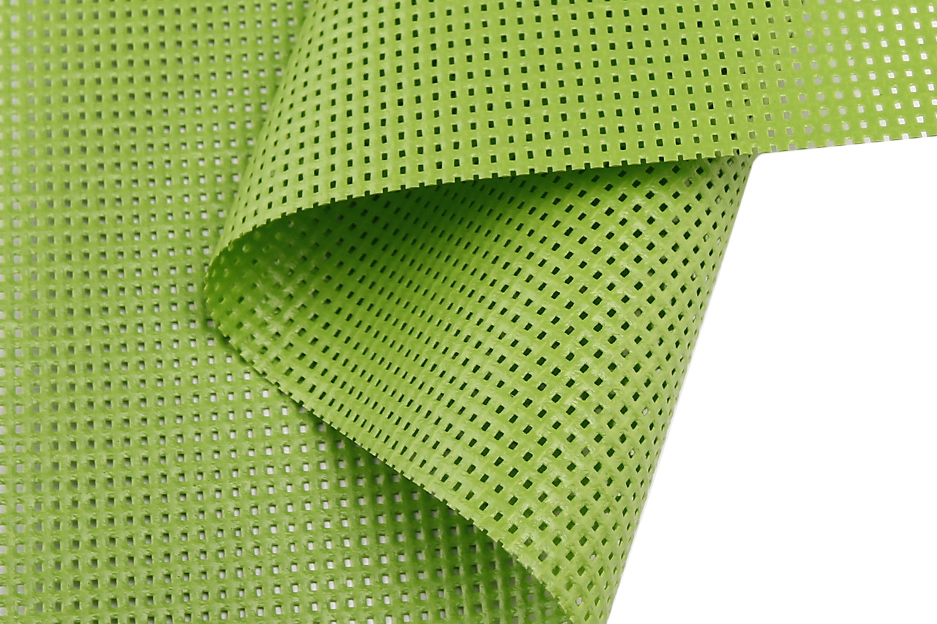

• Customizable Colors: The color of PVC tarpaulin can be customized according to customer requirements to meet specific aesthetic demands.

• Wide Range of Applications: Due to its versatile characteristics, PVC tarpaulin finds applications in various fields, including truck covers, tents, pool covers, etc. Different surface textures and properties cater to different purposes and environments.

PVC tarpaulin is a multi-layer fabric comprising PVC film and a fiber reinforcement layer. It boasts exceptional strength, flexibility, and adaptability, making it suitable for a broad range of applications. Furthermore, it can be customized to meet specific needs and aesthetic preferences.

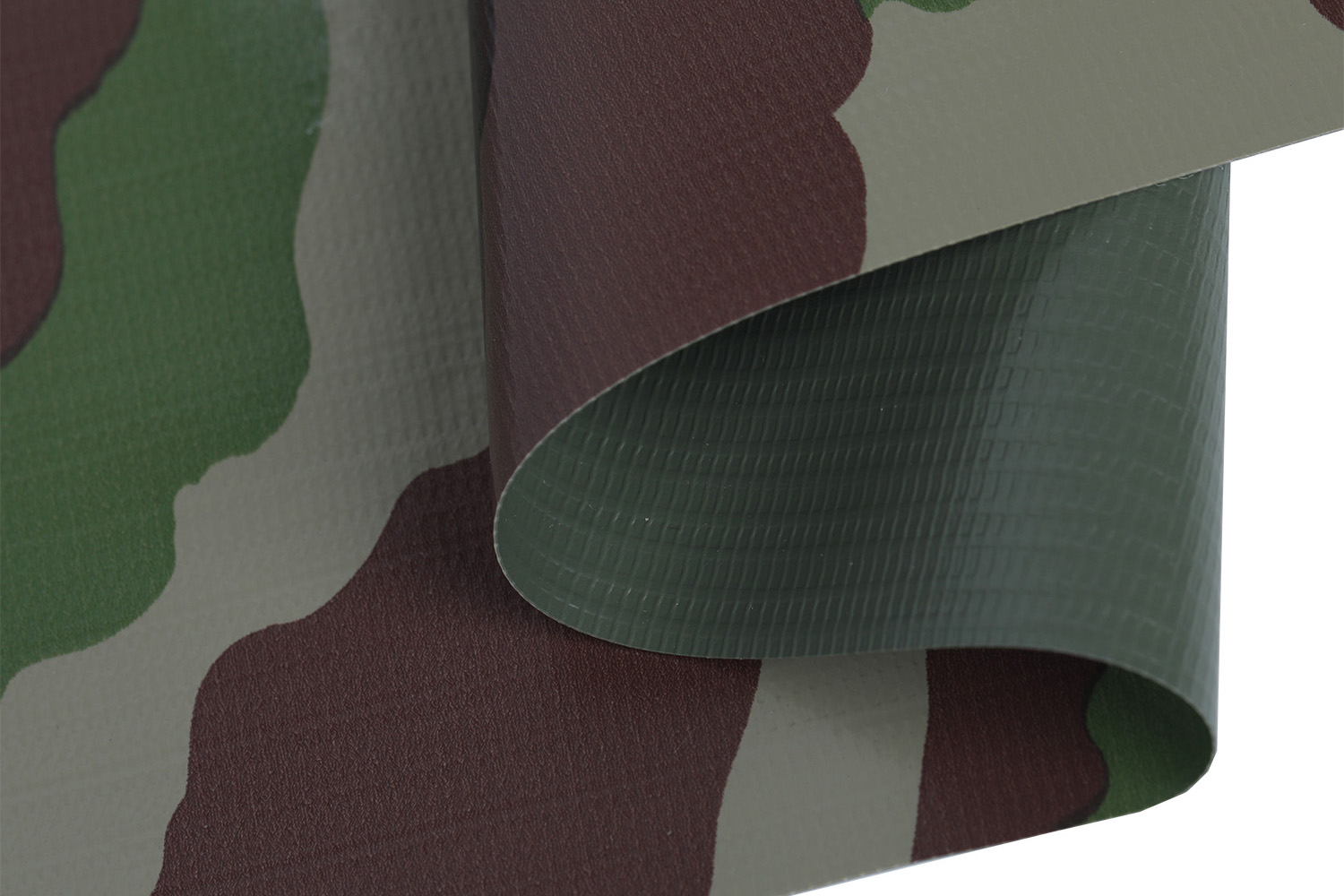

Printed Camouflage Tent Tarpaulin

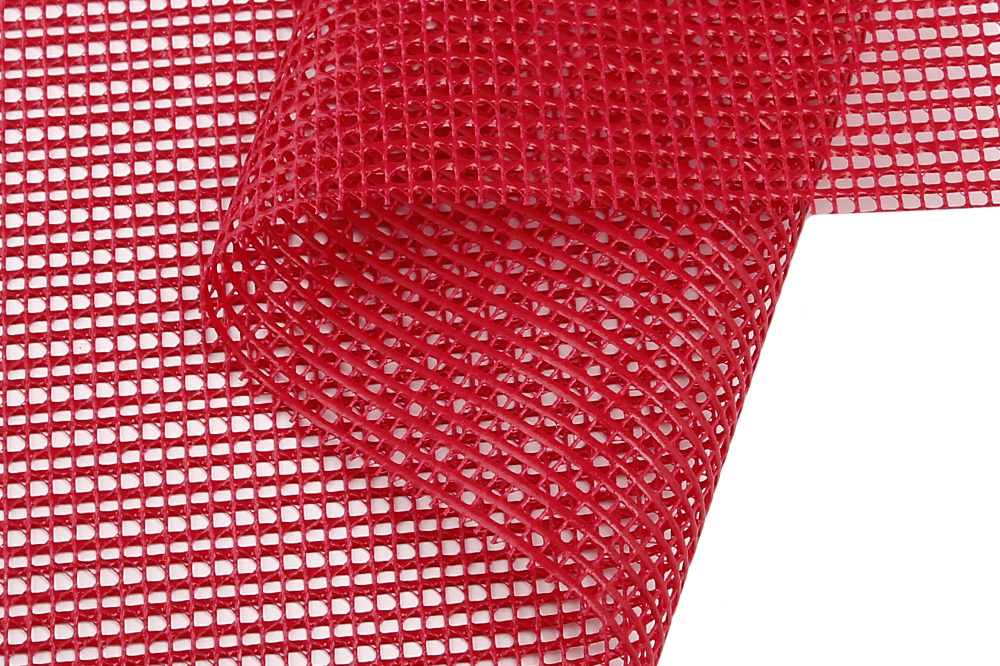

Colorful Mesh Fabric

Textilene Fabric

Striped Awning Fabric

Sunshade Mesh Fabric

Construction Safety Mesh

Machine Cover

Boat Cover

PVC Film

Medical Mattress Fabric

Inflatable Bouncer/Castle

Top Pool Cover

Building Membrane

Industrial Curtain Walls

Frame Swimming Pools

Stationery Bag Fabric

Laminated Tent Tarpaulin

Inflatable Boat

Container Cover

Trailer Cover

Suitcase & Waterproof Bag Fabric

Fast Shutter Door

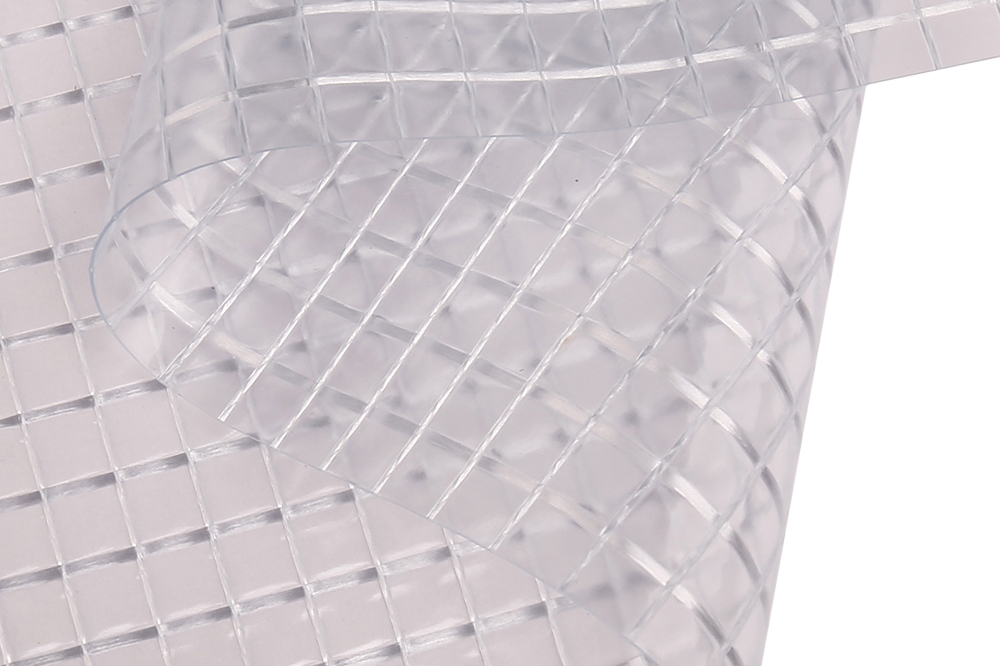

Thermal Insulation Materials (Window)

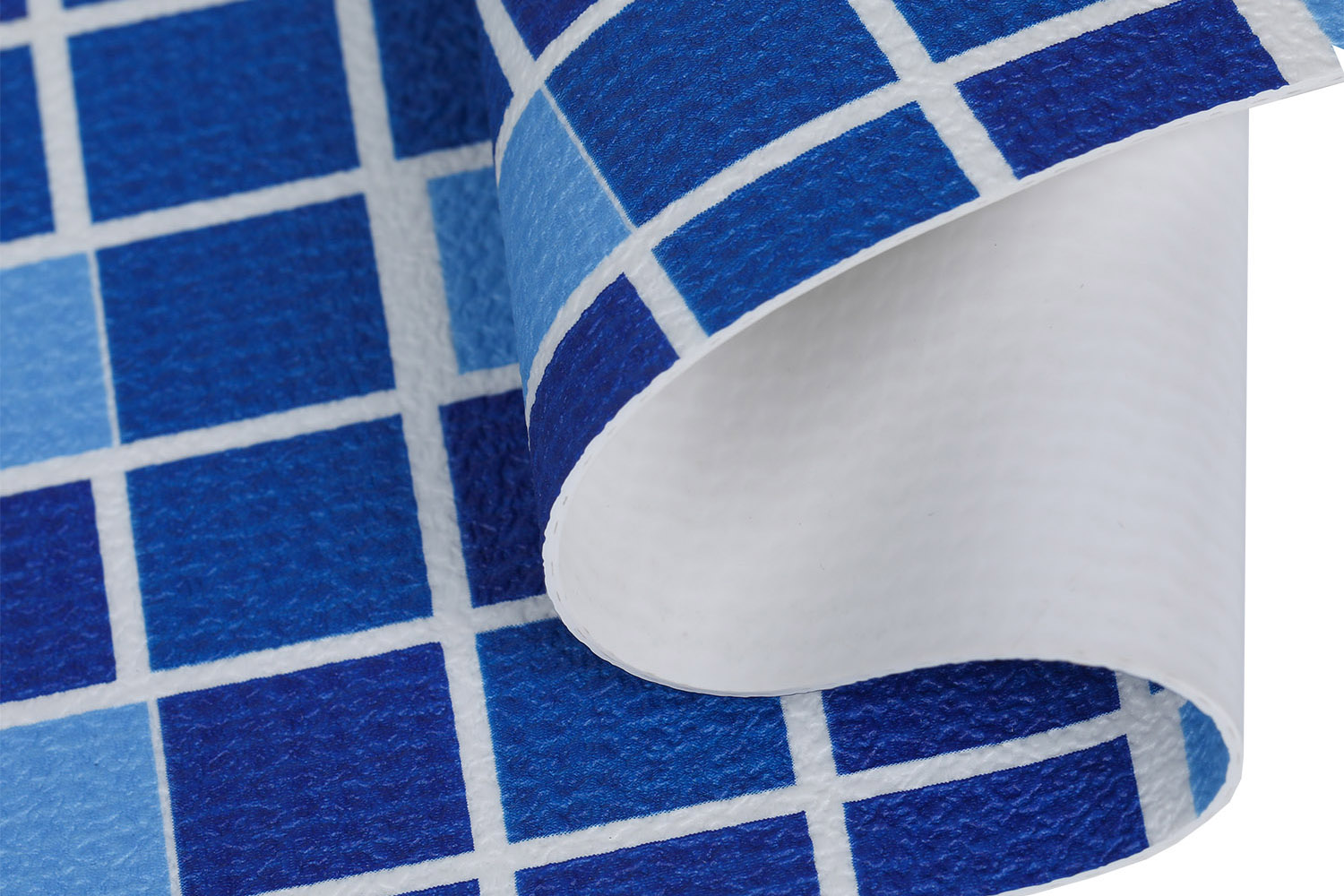

Pool Liner

Pickup Cover

Wading Protective Clothing

Ventilation Ducts

Oil Boom

Trampoline Wrapping Fabric

Collapsible Bucket

Water Storage Bladder

Gym Mat

Pet Mat

Garage Floor Mat

RV Awning Replacement Fabric

RV Awning Sun Shade

Baby Safety Gate

PVC Truck Cover

Inflatable Tent

Coated Tent Tarpaulin

Truck Side Curtain

Ground Floor Cloth

DWF