We often see many promotional banners for organizations and events on the roads and highways, and flex banners are one of the common types for promotions.

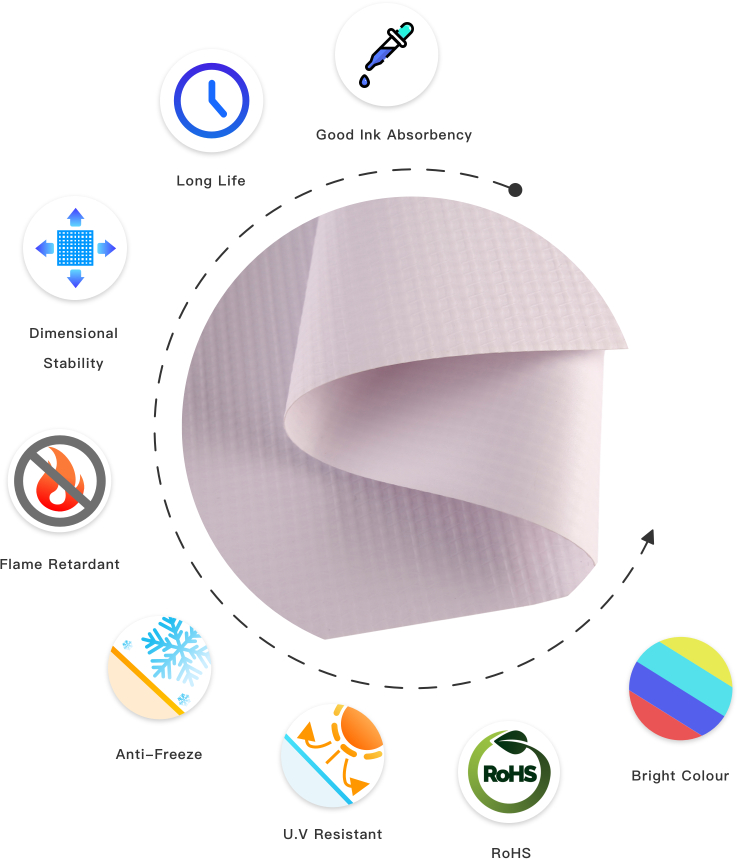

Flex banners are made of PVC material so they are also called PVC flex banners, because they are made from PVC material containing organic compound mixture, they are light in weight and flexible yet still very abrasion resistant. It can be used both indoors and outdoors both as the material used is harmless. They are also relatively cheap and affordable compared to the other advertising platforms like television.

Flex banners are available in various types such as frontlit, backlit, blackout , flexible banners,Printing Mesh,PET Flex ,Self Adhesive Vinyl,One Way Vision. Customers can choose flexible banners according to your different requirements such as event promotion, product launch or roadside billboards.

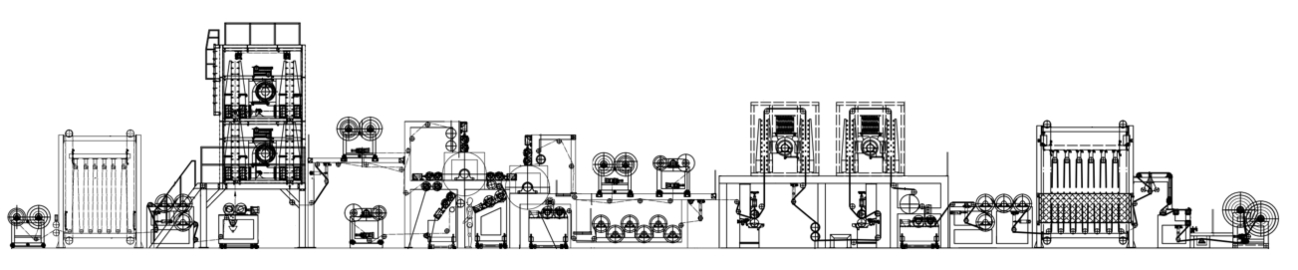

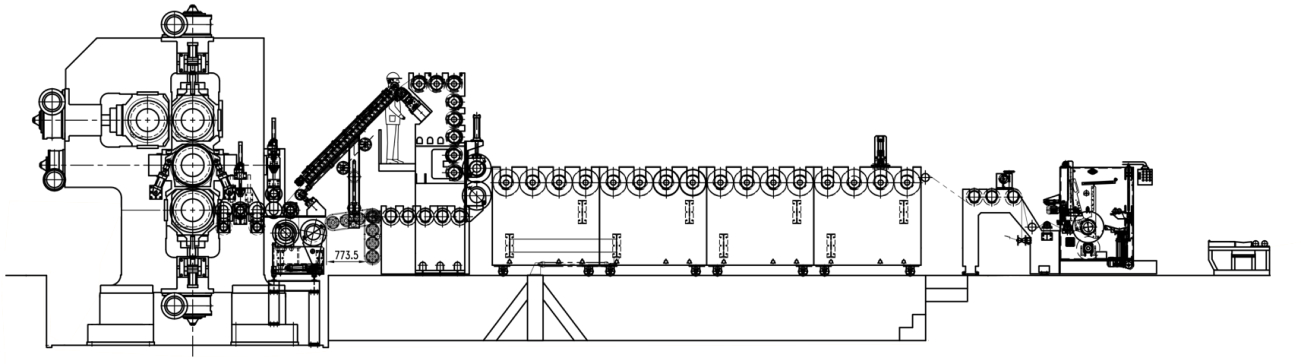

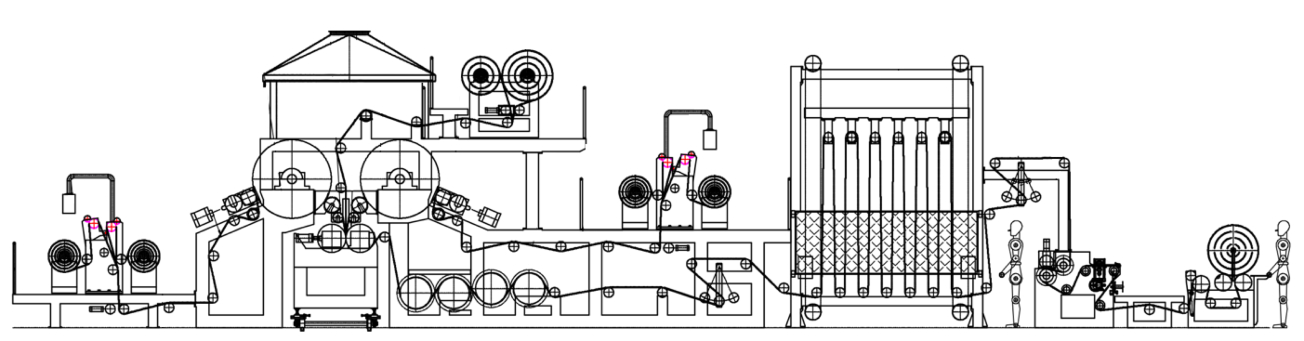

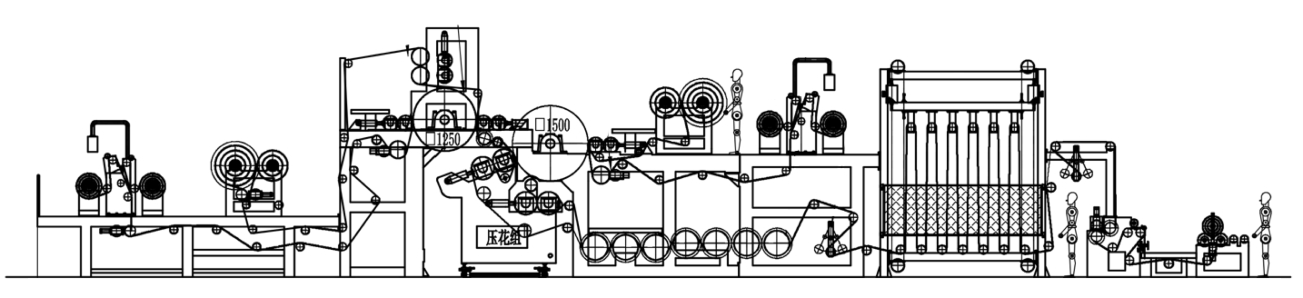

In the manufacturing process of flex banner fabrics, various machines are employed for different fabric specifications:

- Calendering Machine: Transforms PVC raw material into paste and calenders it into different thicknesses of PVC film using a roller system. The film is bonded to polyester backing and finished with gloss, matte, or embossed textures.

- Cold Lamination Machine: Used for laminating PVC films onto polyester fabric quickly and cost-effectively, often for lower-priced products.

- Hot Lamination Machine: Advanced version of cold lamination, offering higher quality and durability. It can apply acrylic coatings for self-cleaning and enhance adhesion for semi-coated PVC tarpaulin.

- Semi-Coated Machine: Its primary task is to bond two or more different materials together through coating or adhesive, creating a composite material. This can provide enhanced strength, waterproofing, and other performance characteristics.