Product Name: Microweave Shade Fabric

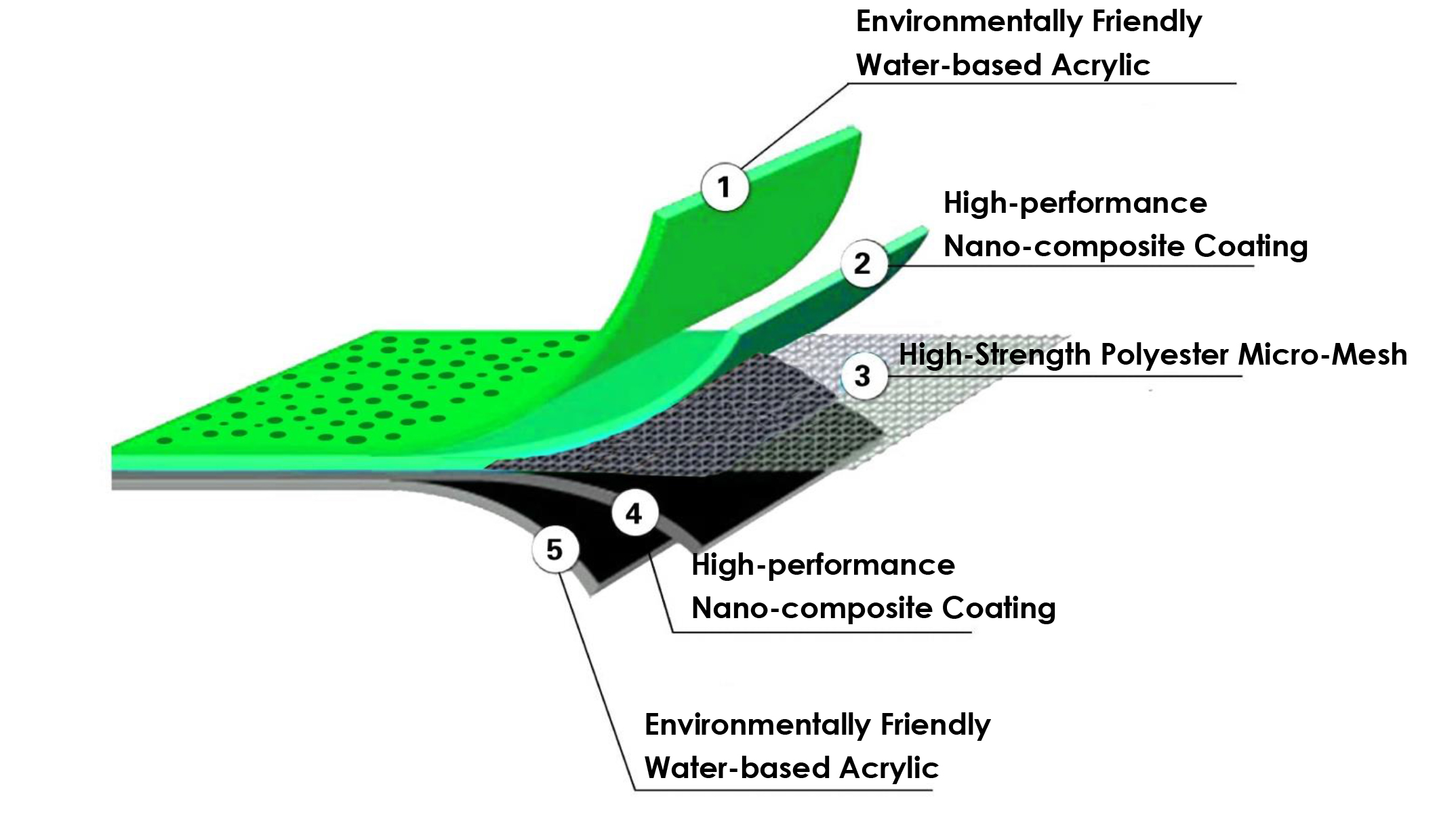

Product Features: Microweave Shade Fabric is woven from ultra-low shrinkage and ultra-high strength industrial polyester fiber filaments, and then produced with a complete high-performance nano-composite coating. Finally, the entire fabric is completely wrapped in environmentally friendly water-based acrylic at one time. The fabric has a smooth, clean surface and is highly resistant to stains.

Application: Our products are widely used for roller blind, facade blind, lateral pergola blind, retractable pergola roof and shade-sail, etc.

| Items | Test Result | Test Method |

| Composition | Polyester + Polyvinyl Chloride (PVC) + Water-Based Acrylic Paint | |

| Weight (GSM) | 400g/m²±5% | GB/T4669-2008 |

| Thickness | 0.50mm ±0.02 | DIN53354:1981 |

| Openness Factor | 3% | FZ/T01009-2008 |

| Tensile Strength | Warp 3200N/5cm±5%Weft 3000N/5cm±5% | EN ISO 1421 |

| Tearing Strength | Warp 600N/5cm±5%Weft 500N/5cm±5% | DIN53363 |

| Abrasion Resistance | >10000 | ASTM D4966 |

| Light Fastness | 7 | GB/T8427-2008/ ISO 105 B02/ ATCC |

| FR Certification | B1M2NFPA701 Method 1&2 | GB 50222-95/DIN4102-1 NFP92-503 NFPA701 |

| Environment | J/T307-2006 OEKO-TEX STANDARD 100CLASS ZV GREEN GUARD ECOSPECIFIER CETEC ROSH/REACH | |

| Roll Length | 30M / 35M / 40M / 50M | |

| Width | 2M (79") / 2.5M (98") / 3.2M (126") | |

| Cutting | Cold Cutting, Ultrasonic Cutting, Crush Cutting or Laser Cutting | |

| Welding | Thermal, High-Frequency, Ultrasonic or Sewing | |

| Cleaning | Use a Soft Brush or White Cloth, Rinse with Water or Wipe with a Damp Sponge | |